Horizontal Move

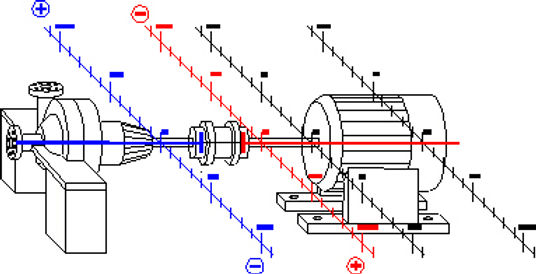

The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. View the machine from the pump end, zero the indicators on the left, and then rotate and read on the right. Make sure that you always view the pump from the same direction in order for you to keep the left and right directions correct. There is no sag compensation on the horizontal move.

For example:

the indicator on the pump reads -8

the indicator on the motor reads +10

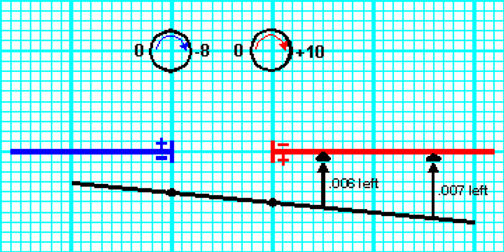

The shafts are collinear at 1/2 the Total Indicator Reading.

Using graph paper to illustrate the position. Under the indicator position mark the point that is 1/2 the indicator reading. (-4 for the pump and +5 for the motor) Connect these points and extend the line past the motors feet. This will show you how much you need to move the motor for horizontal alignment.

These indicator readings mean that you need to move the motor:

front foot .006" left

back foot .007" left

You can avoid graphing the horizontal move by zeroing the indicators on the left and rotate them to right. Now turn the indicator needles halfway to zero and begin to walk the motor into place by moving the farthest foot toward zero and then the nearest foot. Slowly walk the motor into place by alternating the moves until you obtain two zero indicator readings.

Now begin the procedure for the vertical move. Be sure to check your equipment for sag and soft foot.